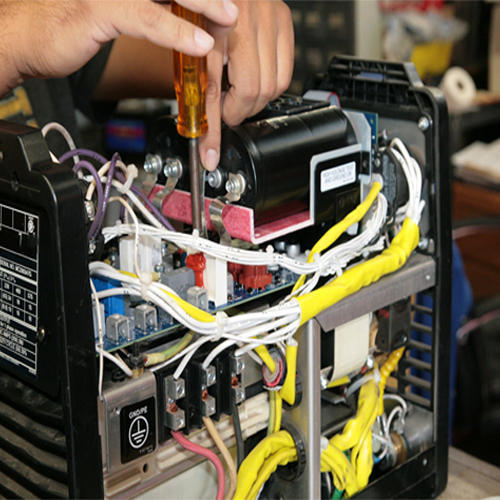

REPAIR

Swift welding machine repairs with proven excellence. We guarantee a fast turnaround to keep your machinery running smoothly. With comprehensive welding machine repair solutions we will quickly get you back to your job.

Wherever possible we offer ‘Same Day Call-Out Service’ When prompt attention to your machine is requested to ensure minimum ‘down time’. We also offer ‘Off Site Repair’. We will collect your machine for assessment back at our workshop and return the repaired set back as soon as possible.

All repairs are conducted safely and tested.

Torch, machine and tool repairs are also available upon request.

SERVICING

Preventative maintenance is the best way to keep costs down! Our main aim is maximising the potential of your machine for as long as possible. We are pleased to offer a fully comprehensive and managed maintenance programme for ALL your welding equipment. Benefits of this include; reduce down time, increase in work capacity, a safer and cleaner working environment and reduce any unnecessary call out charges.

CALIBRATIONS

Optimise your welding performance with annual calibrations this ensures compliance and reliability for your welding machine. Calibrations should be done annually by qualified professionals to ensure production work is carried out with the applicable standards.

Equipment calibrated to UKAS standards, aligning with BS EN ISO / IEC 17025-2017 meeting aviation and Rolls Royce standards.

Calibrations should be done annually by qualified professionals to ensure production work is carried out with the applicable standards.

GAS SAFETY CHECKS

Comprehensive gas safety inspections which cover regulators, flashback arrestors, hoses, fittings, and blowpipes.

Workplace safety with our thorough CP7 & CP47 Gas Equipment Safety Checks. You can rely on our qualified engineers with in-depth knowledge of oxy-fuel gas equipment, effectively addressing any defects and hazards. Receive a report detailing inspection findings, actions taken, spare parts fitted, and a certificate for added assurance.

It is a legal requirement to ensure that equipment used in the workplace is in a safe condition, well maintained and is inspected regularly.

Failing to comply with safety regulations can result in hefty fines, legal action, and even loss of life. That’s why getting your equipment inspected regularly is not an option, but a must.

ARC RECOMMENDS

We recommend Calibrations, Repairs, Servicing and Maintenance are carried out at 12-monthly intervals.

Please feel free to contact us with any questions and enquires.